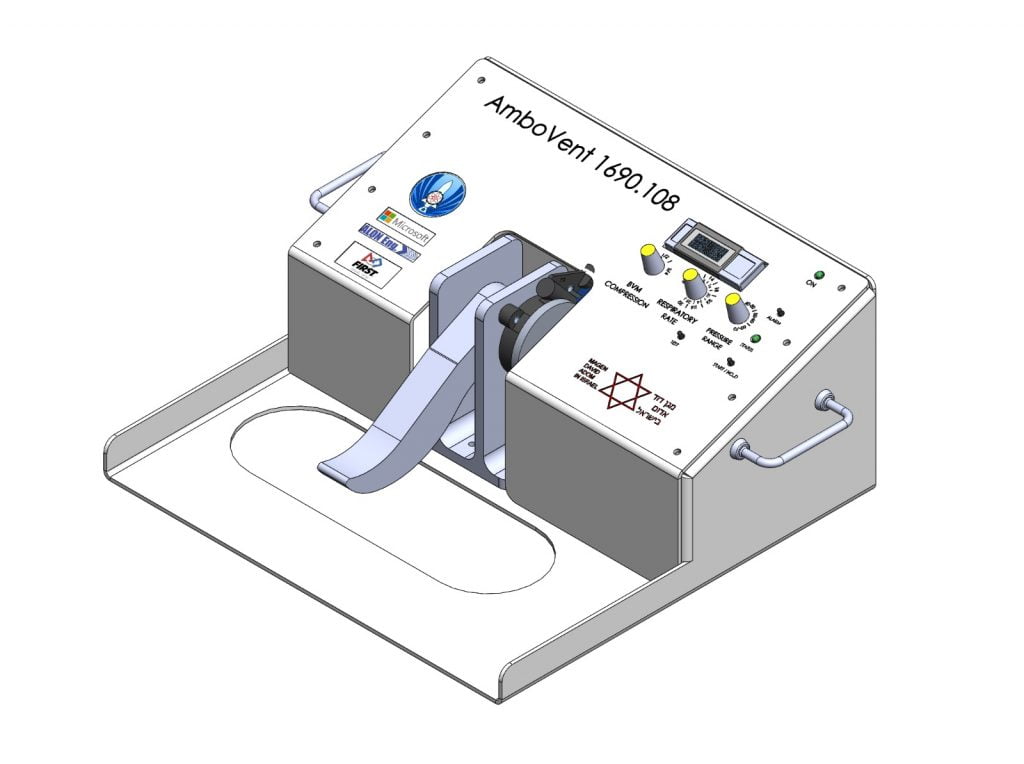

Israel’s Magen David Adom ambulance service began manufacturing low-cost and easy to assemble ventilators. (Provided photo)

By Eli Jaffe, EMT-P, PhD

The COVID-19 pandemic raises the need from EMS to transfer patients from heavily affected regions to hospitals that have the capability to provide more advanced treatment – particularly for those ventilated and in need of intensive care. In addition, global demand in procuring ventilators, and lack of readily supply raises the need for self-sufficiency in acquiring or creating new ventilator prototypes.

Magen David Adom (MDA), along with partners from the Defense and Medical industries, has begun manufacturing low-cost ventilators as world supply is strained. All ambulances carry on board basic manual ventilators in the form of Ambu-bags (BVM), and the new proposed prototype will allow them to be easily converted into automatic ventilators.

As Israel’s nationally mandated ambulance service, MDA initiated the prototype creation in partnership with Israel’s Air Force, Israel Aerospace Industries, Microsoft and other partners including the United States-based FIRST (For Inspiration and Recognition of Science and Technology) Israel robotics competitions, a leading robotics competition for high schools that aims to encourage engineering and science in schools worldwide.

The goal of developing this device was to create an easy to build, affordable, simple and available automated BVM machine designed with 3D printed parts. The prototype design has already been shared online as an open-source design for other countries to use and improve upon, though it has not yet been approved for clinical use, as it needs special FDA-like approval.

MDA Paramedic and medical engineering student Yuval Eran, who is currently doing an internship focusing on medical machinery and devices and participated in one of Israel’s FIRST teams in high school, made the connection between the organizations, as well as Israel’s Air Force, that put out a call on March 18th for new ventilator prototypes.

“We are preparing for a situation like in Italy or Spain where too many patients are in critical condition and need mechanical ventilation, but there are not enough machines,” Eran said. “People are dying because there are not enough machines to ventilate patients.”

Although automated ventilators are currently in the mobile ICU units, MDA might be required “to transport a lot of ventilated patients between hospitals,” requiring some 800 ambulances to upgrade from their manual ventilators, according to Magen David Adom Director General Eli Bin.

“Those ventilators will form the necessary backup required for mass-evacuations and will be used as a vital reserve for hospitals,” said Bin.

“When there is a shortage of ventilators, the importance of one for saving lives is enormous,” added Magen David Adom Medical Director Dr. Raphael Strugo.

“The COVID-19 seriously damages the lungs, and the health services system might find itself with a shortage. The machine that enables ventilation using the automation of the ventilators will allow for rapid response during crisis,” Strugo added.

Heeding the call, MDA organized into teams to work on the machine, working around the clock and completed a prototype just three days later using available materials to create an easy to build option. One day later, the prototype was used in its first hospital round to receive expert opinions and recommendations for improvement. After 13 days, there was a fully working prototype, and it was presented to a committee of representatives from Israel’s Ministry of Health and Defense.

The ventilator prototype is based on the bag valve mask used for short-term intubated patients, but with a mechanical function that rids of the need for a pair of hands to squeeze the standard bag valve mask.

Though there are various prototypes that have been created to date, other machines have not successfully accounted for the various parameters necessitated by ventilation profile, including a patient’s respiratory rate and resistance pressure of his or her breathing.

MDA’s prototype can be made in just several days, and costs $200-$500 per piece.

Companies around the world that have the ability to mass-make such machines are taking note, with MDA’s prototype likely to be seen soon in Israel and abroad, as more than 30 countries having reached out for MDA’s solution.

Though the basic ventilator solution should only be used as a on the least complicated intubated patients and where traditional ventilators are not available, the solution could be life-saving for hundreds of thousands of people.